The harvest

For a long time, the harvest was done by hand or by beating (use of a long stick beating the olive branch to make olives fall down), nowadays these methods are still used (beating is only used for small olives, firm flesh which do not risk to be damaged), but they are completed or replaced by different tools more or less mechanized: manual comb, mechanical comb, vibrator… By hand, olives are harvested in a basket (in plastic or a wicker basket) that the picker wears around his neck. To be transported, olives are put in plastic perforated boxes or pallox and are quickly brought to the olive mill.

The arrival at the mill

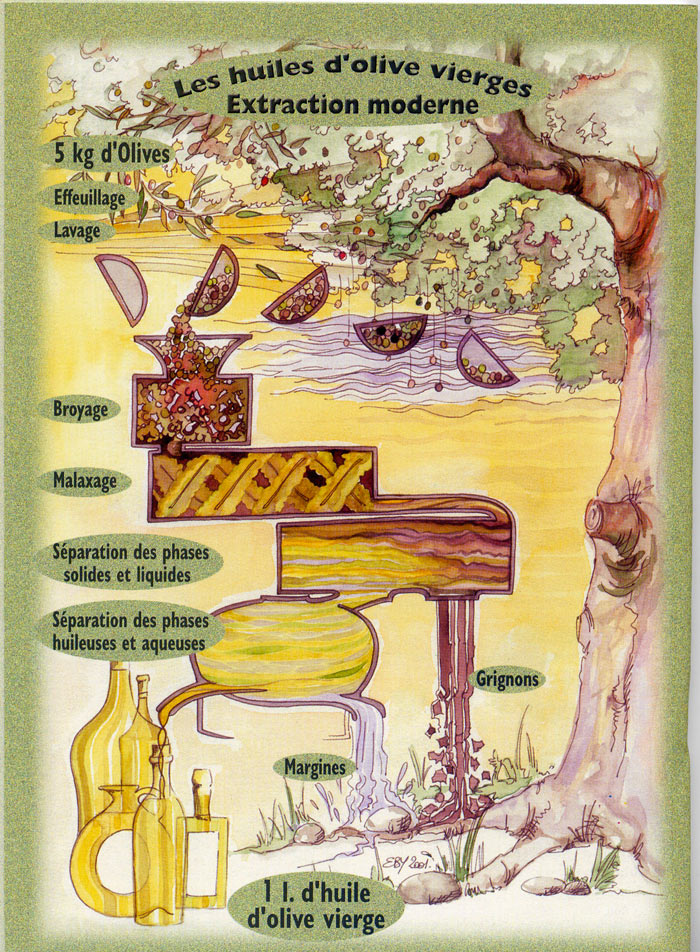

The olive cannot be consumed as it is, it has to be prepared to be consumed for table or for the oil extraction. That’s the profession of the olive miller, he is in charge to extract the elixir of this small fruit. At the mill arrival, olives are cleared of leaves which may have fallen in the basket or net (this step is sometimes made directly in the olive orchard) and washed.

The extraction of the elixir

Then, direction the millstone or crusher to be crushed and transformed into a paste which will be kneaded to put together the small olive oil drops in bigger drops and make oil extraction easier. The kneading has to be soft and lasts about 20 to 30 min. It is made thanks to the millstone (which crushes and kneads at the same time) or to a mixer (an endless screw turns slowly the paste in a cylinder). When the paste is ready, the extraction of liquids (water + oil) contained in the paste can begin. In the “traditional” system (indicated on the label by the mention “first cold pressure”), the paste is installed on filters called “scourtins” which are piled around an alternated axis with a metal disk (about 5 scourtins and then a metal disc helps for pressure). The scourtin trolley is then placed in a hydraulic press which will, thanks to the pressure, bring the oil and water out of the olives. In the “continuous” system (identified by the facultative mention “cold extracted”), the paste goes in the centrifuge which, by turning, will naturally separate paste from water and oil having different densities. The extracted oil is stored in a stainless steel tank. Before bottling, the oil can be filtered. The filtration allows removing small impurities that oil can contain and which come from the olive flesh. The filtration modifies nothing in the taste but allows a better long term preserving.

Good to know: we need 5 to 6 kilos of olives to produce one liter of olive oil.